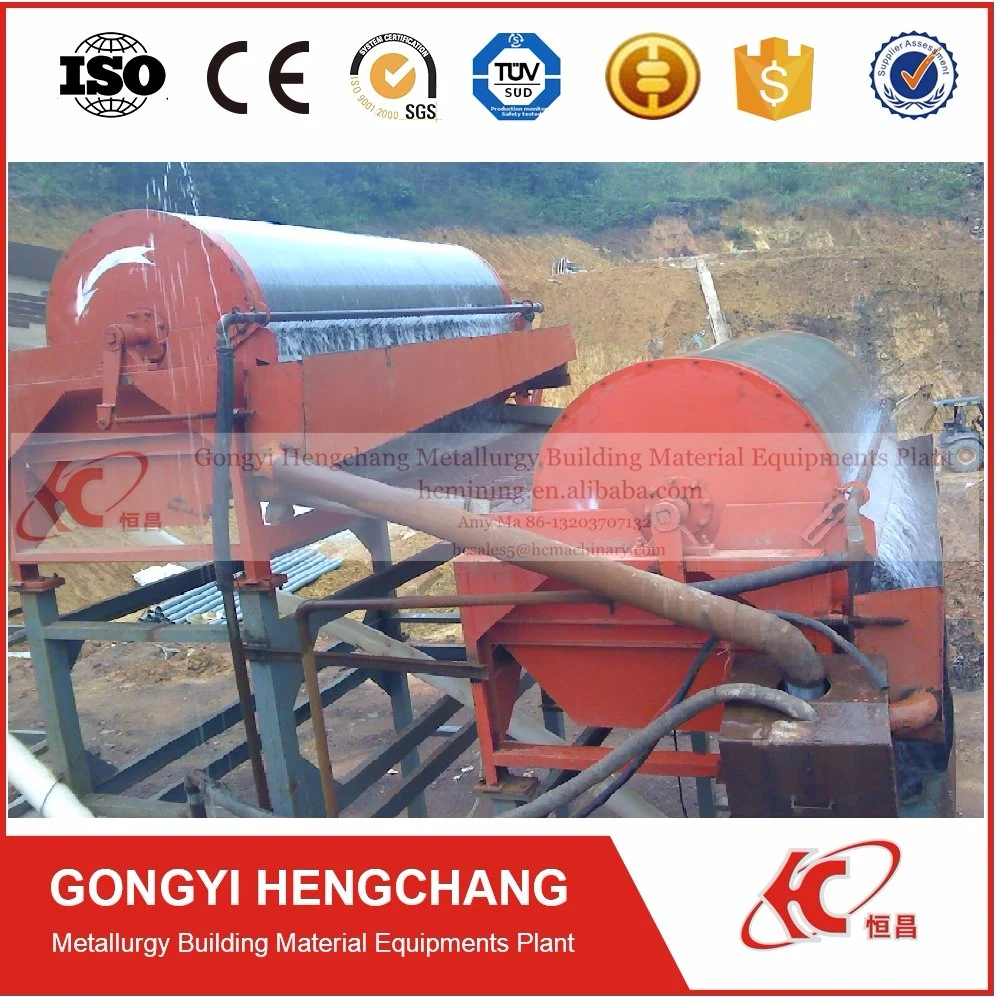

Product name: Factory direct supply Wet fine magnetic separator for magnetic metal separation

1. Specifications

Condition: New

Type: Magnetic Separator

Production Capacity: High

Place of Origin: Henan, China (Mainland)

Brand Name: HENGCHANG

Model Number: CTB

Voltage: Clients Local Standard

Power(W): Different model

Dimension(L*W*H): Different Model

Weight: According to different models

Certification: ISO9001:2015, CE

Warranty: 12 Months

After-sales Service Provided: Engineers available to service machinery overseas

Product name: Factory direct supply Wet fine magnetic separator for magnetic metal separation

Application: for wet magnetic separating of magnetite, roasted ore, and ilmenite

Installation: Engineers Guide

The Machines classification: magnetic separation equipment

Keywords: separator, magnetic separator, wet separation machine

After sale service: Life-long Service

Spare Parts Supply: Life Long Provide

Usage: magnetic separation, iron removal

Color: Customized

Packaging Details: Standard Export Packing.

Delivery Detail: within 15 days after payment

2. Brief introduction of Factory direct supply wet high-intensity fine magnetic separator for magnetic metal separation:

The wet magnetic separator is applicable for the wet-magnetic separating of strong-magnetic materials with particle size less than 3mm, such as magnetite, roasted ore, and ilmenite, etc. In addition, it is also widely used for iron removal in coal, nonmetal ore and building material industry.

Our factory can supply series of magnetic separators with different magnetic force, such as downstream type, counter-current type and half counter-current type.

3. Technical Parameters of Factory direct supply wet high-intensity fine magnetic separator for magnetic metal separation:

4. Main features of Factory direct supply wet high-intensity fine magnetic separator for magnetic metal separation:

1). Reasonable and simple structure, easy for installation, operation and maintenance.

2). Applicable for wet process.

3). Permanent magnetic shell, the magnetic intensity on the shell surface can be designed according to actual application.

4). Strong processing capacity and low maintenance cost.

5. Working principle of Factory direct supply wet high-intensity fine magnetic separator for magnetic metal separation:

When the raw materials flow into the tank body, the flowing direction of the raw materials is the same as the rotary direction of the magnetic drum, the iron magnetite materials are attracted to the surface of drum. This is the first separation.

The second step: the flushing water below flush the raw materials back, this time the flowing direction of the raw materials is opposite to the rotary direction of the magnetic drum. Then along with the rotation of drum, the iron magnetite materials on the surface of drum will finally leave the magnetic field and fall in the ore concentrate box under the effect of gravity. The flushing water above helps to flush the iron magnetite into the ore concentrate box. The weak magnetic and non-magnetic materials can not be attracted and will flow to the discharge pipe as tailings.

7. Packing & Delivery

8. FAQ

1). Q:Installation

A: According to clients request, we can provide installation technicians to supervise and assist in the assembly and commissioning of the equipment. Travel and accommodation costs, plus USD80 per day per one to be met by the client.

2). Q:Payment

A: 30% by T/T by order + 70% before shipment.

3). Q: What about Warranty? what will we do if the machine is broken down?

A: The warranty period for all of Hengchang's structural and mechanical equipment is normally one year. The warranty period for all electric motors is six months. Wear parts are not covered in warranty unless the component part is found to be flawed.

4). Q: What should we do if we want to get a best quotation?

A: If you want to get the correct and exact selection of the model earlier, please help us with following information

a. the capacity (tons per hour ). b. input and output size. c. stone material to be crushed.

5). Q: What could you help me to do for the business ?

A: Highly appreciate your trust , we can provide you with proposal chart for complete production lines , spot inspection and operation training according to your demands and the conditions of applied spot.

6). Q: What's your after-sales Service?

A: All equipment provided by Hengchang is with the highest standard and very few customer complaint. If any problems occured, our team of Engineers and Technicians will respond within12hours. And after selling, we keep monitoring the operation situation about our machines monthly.

7). Q:Delivery time

A: Standard delivery time for stationary crusher plant is 25 days from receipt of deposit., for the mobile crusher plant is 35 days.

1. Specifications

Condition: New

Type: Magnetic Separator

Production Capacity: High

Place of Origin: Henan, China (Mainland)

Brand Name: HENGCHANG

Model Number: CTB

Voltage: Clients Local Standard

Power(W): Different model

Dimension(L*W*H): Different Model

Weight: According to different models

Certification: ISO9001:2015, CE

Warranty: 12 Months

After-sales Service Provided: Engineers available to service machinery overseas

Product name: Factory direct supply Wet fine magnetic separator for magnetic metal separation

Application: for wet magnetic separating of magnetite, roasted ore, and ilmenite

Installation: Engineers Guide

The Machines classification: magnetic separation equipment

Keywords: separator, magnetic separator, wet separation machine

After sale service: Life-long Service

Spare Parts Supply: Life Long Provide

Usage: magnetic separation, iron removal

Color: Customized

Packaging Details: Standard Export Packing.

Delivery Detail: within 15 days after payment

2. Brief introduction of Factory direct supply wet high-intensity fine magnetic separator for magnetic metal separation:

The wet magnetic separator is applicable for the wet-magnetic separating of strong-magnetic materials with particle size less than 3mm, such as magnetite, roasted ore, and ilmenite, etc. In addition, it is also widely used for iron removal in coal, nonmetal ore and building material industry.

Our factory can supply series of magnetic separators with different magnetic force, such as downstream type, counter-current type and half counter-current type.

3. Technical Parameters of Factory direct supply wet high-intensity fine magnetic separator for magnetic metal separation:

| Model No. | Magnetic strength | Input size | Cylinder speed | Power | Capacity | Weight | |

| mT | mm | r/min | kw | Ore (t/h) | Slurry(m³/h) | kg | |

| CTB600×900 | >=120 | <=1 | 40 | 1.1 | 8-15 | 24 | 850 |

| CTB600×1200 | >=120 | <=1 | 40 | 1.5 | 10-20 | 32 | 1000 |

| CTB600×1800 | >=120 | <=1 | 40 | 2.2 | 15-30 | 48 | 1300 |

| CTB750×1200 | >=120 | <=1 | 35 | 2.2 | 15-30 | 48 | 1500 |

| CTB750×1800 | >=120 | <=1 | 35 | 3.0 | 20-45 | 72 | 1800 |

| CTB900×1800 | >=135 | <=1 | 28 | 4.0 | 25-55 | 90 | 2400 |

| CTB900×2100 | >=135 | <=1 | 28 | 4.0 | 30-65 | 100 | 2650 |

| CTB1050×1800 | >=145 | <=1 | 22 | 5.5 | 35-70 | 110 | 3800 |

| CTB1050×2100 | >=145 | <=1 | 22 | 5.5 | 45-88 | 140 | 4150 |

| CTB1050×2400 | >=145 | <=1 | 22 | 5.5 | 45-88 | 140 | 4500 |

| CTB1200×2100 | >=145 | <=1 | 19 | 7.5 | 62-110 | 160 | 5800 |

| CTB1200×2400 | >=145 | <=1 | 19 | 7.5 | 82-120 | 192 | 6200 |

| CTB1200×3000 | >=145 | <=1 | 19 | 7.5 | 80-150 | 240 | 6800 |

| CTB1500×3000 | >=145 | <=1 | 14 | 11 | 90-170 | 270 | 8200 |

| CTB1500×4000 | >=145 | <=1 | 14 | 11 | 115-220 | 350 | 9000 |

4. Main features of Factory direct supply wet high-intensity fine magnetic separator for magnetic metal separation:

1). Reasonable and simple structure, easy for installation, operation and maintenance.

2). Applicable for wet process.

3). Permanent magnetic shell, the magnetic intensity on the shell surface can be designed according to actual application.

4). Strong processing capacity and low maintenance cost.

5. Working principle of Factory direct supply wet high-intensity fine magnetic separator for magnetic metal separation:

When the raw materials flow into the tank body, the flowing direction of the raw materials is the same as the rotary direction of the magnetic drum, the iron magnetite materials are attracted to the surface of drum. This is the first separation.

The second step: the flushing water below flush the raw materials back, this time the flowing direction of the raw materials is opposite to the rotary direction of the magnetic drum. Then along with the rotation of drum, the iron magnetite materials on the surface of drum will finally leave the magnetic field and fall in the ore concentrate box under the effect of gravity. The flushing water above helps to flush the iron magnetite into the ore concentrate box. The weak magnetic and non-magnetic materials can not be attracted and will flow to the discharge pipe as tailings.

6. Our Service

Pre-sale service: Freely provide project designing, process designing, select suitable equipment for you.

Order execution service: Provide equipment layout draw, foundation draw and detail equipment manuals. Timely report you the manufacturing schedule and related photos for keep monitoring.

After-sales service: Dispatch engineer to the site to guide installation, debugging and training operators. Installation and operation workers are offered if you need.

Pre-sale service: Freely provide project designing, process designing, select suitable equipment for you.

Order execution service: Provide equipment layout draw, foundation draw and detail equipment manuals. Timely report you the manufacturing schedule and related photos for keep monitoring.

After-sales service: Dispatch engineer to the site to guide installation, debugging and training operators. Installation and operation workers are offered if you need.

7. Packing & Delivery

| Packaging | |

| Name | Wooden case |

| Weight | According to different models. |

| Packaging Details | 1. The normal package is wooden box. If export to European countries, the wooden box will be fumigated. If container is too tighter,we will use PE film for packing. 2. According to customers special request. |

| Packaging | |

| Name | Export Standard Container |

| Weight | According to different models. |

| Packaging Details | Standard Export Container, motors and the spare parts are packed in wooden case. |

8. FAQ

1). Q:Installation

A: According to clients request, we can provide installation technicians to supervise and assist in the assembly and commissioning of the equipment. Travel and accommodation costs, plus USD80 per day per one to be met by the client.

2). Q:Payment

A: 30% by T/T by order + 70% before shipment.

3). Q: What about Warranty? what will we do if the machine is broken down?

A: The warranty period for all of Hengchang's structural and mechanical equipment is normally one year. The warranty period for all electric motors is six months. Wear parts are not covered in warranty unless the component part is found to be flawed.

4). Q: What should we do if we want to get a best quotation?

A: If you want to get the correct and exact selection of the model earlier, please help us with following information

a. the capacity (tons per hour ). b. input and output size. c. stone material to be crushed.

5). Q: What could you help me to do for the business ?

A: Highly appreciate your trust , we can provide you with proposal chart for complete production lines , spot inspection and operation training according to your demands and the conditions of applied spot.

6). Q: What's your after-sales Service?

A: All equipment provided by Hengchang is with the highest standard and very few customer complaint. If any problems occured, our team of Engineers and Technicians will respond within12hours. And after selling, we keep monitoring the operation situation about our machines monthly.

7). Q:Delivery time

A: Standard delivery time for stationary crusher plant is 25 days from receipt of deposit., for the mobile crusher plant is 35 days.