Tag:Stainless Steel 316L Magnetic Bottom Mixer/Magnetic Stirrer

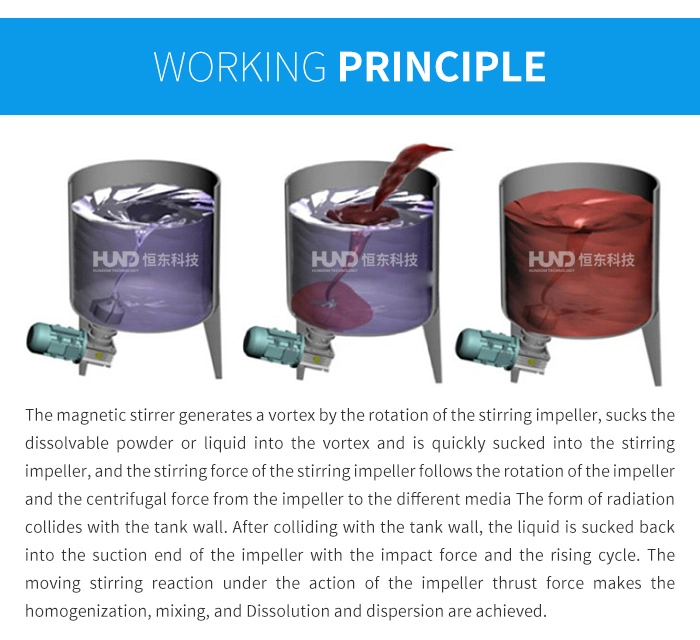

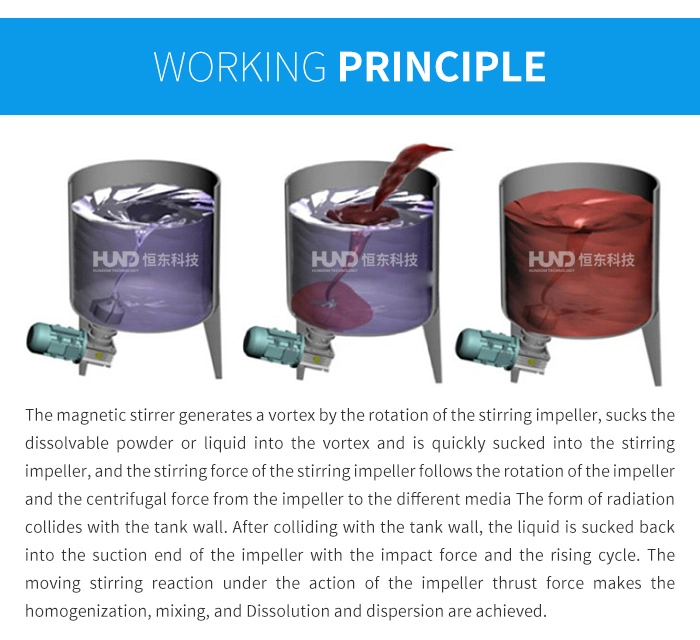

Working Principle

The magnetic agitating is an application of a magnetic coupling.Because the repulsion between the different poles of the magnetic material ,we drive the magnetic agitator by continuous changing the polarity of the magn etic base.

The shaft of motor and reducer connect with the inner magnetic ring.The agitation shaft connected with the out magnetic ring.The out magnetic ring rotates with the inner magnetic ring, and make the agutation shaft rotate according,the inner ring and out ring are separated by a seal cover.The reactor cavity and the out environment are separated by the seal cover.So it is one of the most reliable No-leak design, and a necessities for no-leak reactors.

Technical Parameters

Features

Static dead sealing through welding isolative sleeve replace dynamic mechanical sealing, which can completely solve the leaking problem of mechanical sealing.

Simple structure, east to dismantle, easy to clean, no dead space.

mixing unit is installed on the bottom ,which can mix under few matter ,with unique mixing oars, and can be suitable to mix various mediums.

Product Show

About HUNDOM

Working Principle

The magnetic agitating is an application of a magnetic coupling.Because the repulsion between the different poles of the magnetic material ,we drive the magnetic agitator by continuous changing the polarity of the magn etic base.

The shaft of motor and reducer connect with the inner magnetic ring.The agitation shaft connected with the out magnetic ring.The out magnetic ring rotates with the inner magnetic ring, and make the agutation shaft rotate according,the inner ring and out ring are separated by a seal cover.The reactor cavity and the out environment are separated by the seal cover.So it is one of the most reliable No-leak design, and a necessities for no-leak reactors.

Technical Parameters

| Model | Motor(kw) | Volume(L) | Speed(r/min) |

| CLB-20 | 0.2kw | 50-200L | 120-1400 |

| 0.4kw | 50-200L | ||

| CLB-40 | 0.55kw | 200-500L | |

| 0.75kw | 200-500L | ||

| CLB-60 | 1.1kw | 500-1000L | |

| 1.5kw | 500-1000l | ||

| CLB-80 | 1.5kw | 800-2000L | |

| 2.2kw | 800-2000L | ||

| CLB-100 | 3kw | 1500-3000L | |

| 4kw | 1500-3000L | ||

| CLB-120 | 4kw | 2000-5000L | |

| 5.5kw | 2000-5000L | ||

| CLB-140 | 7.5kw | 3000-100000L |

Static dead sealing through welding isolative sleeve replace dynamic mechanical sealing, which can completely solve the leaking problem of mechanical sealing.

Simple structure, east to dismantle, easy to clean, no dead space.

mixing unit is installed on the bottom ,which can mix under few matter ,with unique mixing oars, and can be suitable to mix various mediums.

Product Show

About HUNDOM

Guangzhou Hundom Machinery Equipment Co., Ltd.has been manufacturing colloid mill, jacketed kettle, rotor pump, mixing tank and other machinery equipment for 14 years , putting quality as our first consideration. We own a team with rich experience in the field, if you have any question, contact us for the professional answer.

Guangzhou Hundom Machinery Technology Co.,Ltd.

Add:No. 115, No. 7, Haina Industrial Park, Shibi Street, Panyu District, Guangzhou City, Guangdong Province, China

Sales:Shum

Tel:+86-020-89081205

Mobile:+86-138-2213-4643

Welcome to visit our factory !

Guangzhou Hundom Machinery Technology Co.,Ltd.

Add:No. 115, No. 7, Haina Industrial Park, Shibi Street, Panyu District, Guangzhou City, Guangdong Province, China

Sales:Shum

Tel:+86-020-89081205

Mobile:+86-138-2213-4643

Welcome to visit our factory !